×

Search

This machine is mainly used for pressure testing of small diameter spiral welded pipes. It can adopt two sealing forms: polyurethane end face sealing or radial large gap sealing. It is equipped with an oil water balance system, and the computer collects, records, stores, and prints test results. It has the advantages of stable pressure maintaining and high safety. The hydraulic pipe pressure testing machine adopts mature and reliable advanced processes and technologies currently available internationally, with the main goal of detecting the quality of finished products and eliminating stress. The physical quality of the product, production costs, various consumption indicators, and labor productivity meet the requirements of product technology and efficiency.

| Two technical performance: | |

| Test pipe diameter: | Φ254 ~ Φ508mm |

| Test pipe length: | 12000 ~ 18288mm |

| Maximum test pressure: | 13MP |

| Sealed square type: | seal ring seal |

| Test medium: | water |

φ254-φ508 hydraulic testing machine product manual

The test hydrostatic pressure machine is used for hydraulic sealing test of φ254 ~ φ508 pipe. Using manual control, is the company's technical personnel independent design, development.

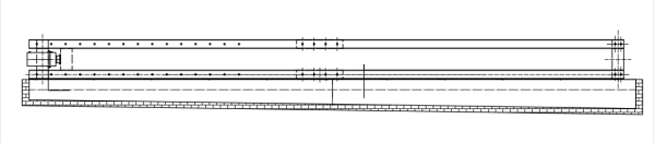

The equipment mainly consists of three parts: the water press body, water supply system, and hydraulic station.

Hydraulic press body:

The hydro pressure testing machine body including: main beam, fixed support, mobile support, mobile sealing head, pipe clamping device:

There are a total of three main beams, one end of which is connected to a fixed support by a column pin, and the other end is supported by a moving support to withstand the axial force generated by the water pressure in the pipe during the hydraulic test.

Located at the positioning end of the pipe and connected to the main beam through six column pins, it is equipped with a water filling valve, a pressure boosting pipe, and a pressure transmitter. The pipes can be filled with water through the water filling valve, and the pressure is increased through the pressurization pipe. The pressurization process is displayed by the pressure transmitter.

The movable support is connected to the movable sealing head by an oil cylinder. The movable support can be moved on the crossbeam according to the length of the pipe, and fixed with column pins after being moved to a suitable position. The movable sealing head is equipped with an exhaust valve for exhaust during pipe water injection. After the clamping device clamps the pipe, the sealing head is moved by the oil cylinder to clamp and seal both ends of the pipe.

The clamping device integrates pipe alignment and clamping, and is placed at both ends of the pipe on the bottom beam of the hydraulic press. It is fixed by a set screw to adjust the position of the pipe, and then the pipe is clamped.

Receiving

↓

to clamp

↓

Move the moving sealing head to clamp and seal both ends of the pipe

↓

Turn on the priming pump to fill the water tank and pipes

↓

After filling with water, close the exhaust valve and open the high-pressure booster pump to pressurize

↓

Hold pressure

↓

Pressure relief and drainage

↓

Seal head retracted

↓

Open clamping device test completed

Φ254mm~Φ508mm hydraulic press

Test pipe diameter: Φ254~Φ508mm

Test pipe length: 12000~18288mm

Maximum test pressure: 13MP

Sealing method: face seal

Test medium: water

Large Diameter Spiral Welded Pipe Production Line

Small Diameter Spiral Welded Pipe Production Line

Heavy Duty Spiral Welded Pipe Production Line

Thin Wall Spiral Welded Pipe Production Line

Stainless Steel Spiral Welded Pipe Production Line

Hydrostatic Pressure Testing Machine for Large Diameter Pipe

Hydrostatic Pressure Testing Machine for Small Diameter Pipe

Hydrostatic Pressure Testing Machine for Ultra High Pressure Steel Pipe

Chamfering Machine for Large Diameter Steel Pipe End

Chamfering Machine for Small Diameter Steel Pipe End

Double Station Chamfering Machine for Steel Pipe

High Frenquency Welded Pipe Production Line for Large Diameter Pipe

High Frenquency Welded Pipe Production Line for Small Diameter Pipe

3PE Anti-corrosion Steel Pipe Production Line

Plastic Coated Steel Pipe Anti-Corrosion Production Line

Polyethylene (PE) Insulated Steel Pipe Production Line

Quick Links

Address

Tel

+86-0317-6213222Quick Links

Address

South Industrial Development Zone, Yanshan County, Cangzhou City, Hebei Province

Phone

+86-0317-6213222